R 310

DESCRIPTION

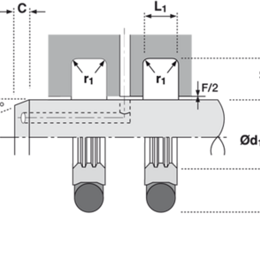

The R 310 rotary seal consists of a profiled PTFE ring filled with carbon (or other filler) and an O-ring. Against aggressive media or higher temperatures, an O-ring made of e.g. FPM can be selected. Type R 310 is designed for rotary and rocking movements, e.g. in rotary converters, rotary drives or machine tool hydraulics. The high wear resistance and low friction ensure smooth movement even at low circumferential speeds without a "stick-slip" effect. This is further supported by the groove on the sliding surface in which the lubricant reservoir is formed. In addition, the contact area is reduced by this groove on the inner diameter, thus increasing the mechanical force distribution. The recess on the outer diameter increases the contact area of the O-ring and minimises the risk of relative movement between the PTFE ring and the O-ring.

Advantages

no stick-slip effect

very low friction

fitting into closed grooves (from piston rod diameter approx. 30 mm)

high temperature resistance

low abrasion and good joint bridging

simple groove shape, small footprint

RECOMMENDATIONS

If type R 310 is used as an end seal, it is recommended to protect the seal with a wiper ring.

MEDIA

The standard version with NBR O-ring is suitable for use in mineral oils between -30 °C and +100 °C. For water and HFA fluids, a temperature range of up to +40 °C is permissible for standard material mating. Resistance to other media must be tested on a case-by-case basis.

Operating conditionsCirculation speed "v" max. 0.5 m/s

Temperature range -30 °C to +100 °C

Maximum pressure 300 bar

Max. p.v. 40 bar m/s