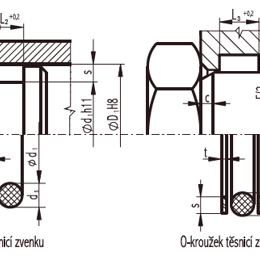

Back-up rings

The material can be selected according to the operating conditions. PTFE is most commonly used. backup rings made of pure PTFE can be used according to the operating conditions and design statically up to approx.

400 bar and dynamically up to approx. 300 bar. For particularly high pressures from approx. 400 to approx. 1600 bar, the retaining rings made of PTFE + filler mixtures, or POM or PA.

For series use with externally sealing retaining rings, it is advantageous to select undivided retaining rings made of PTSM. This material is a special PTFE blend with partial shape memory that shrinks securely to the correct size after assembly using an assembly jig. The retaining rings are not damaged during subsequent assembly of the sealed parts.