CarcoTex SG

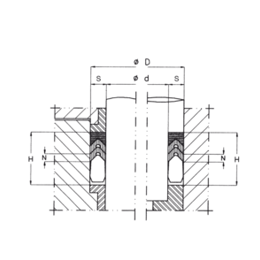

CARCOTEX SG is a classic, straight-through hydraulic seal for both oil and water hydraulic systems. The symmetrical profile allows the SG type to be used as a piston rod or piston seal at working pressures up to 350 bar. It is recommended to be applied to single acting pistons, not double acting pistons.

Kits always consist of:

One flexible sealing ring made of elastomer of characteristic red colour, which has optimum mechanical properties. Even at low pressures, the ring's dimensional preload ensures high sealing capacity and low friction. As the operating pressure increases, the textile rubber V-cuffs are activated through the wedge shape of the ring, ensuring tightness and resistance at high pressure.

One or more V-cuffs made of textile-rubber layers, which are specially rolled and vulcanised in steel moulds during manufacture, ensuring maximum wear resistance in service.

One support ring made of rubber and a special fibre - Kevlar - as standard. This new combination ensures very high anti-extrusion resistance and mechanical strength.

Carcotex / SG offers the following advantages:

The entire set is "floating" in the bay, with axial clearance, which ensures even friction (important, for example, in presses with multiple plungers to prevent crossing).

The radial preload of the flexible sealing ring achieves an optimum sealing effect both in low-pressure operation and at operating deflections of the piston rod.

Easy installation in locations with fixed (non-buildable) building heights.

Eliminates the laborious set-up and adjustment work normally performed with conventional canopy sealant kits.

Caution - the installation principles must be observed!

CarcoTex / SG kits can be supplied with either undivided (standard) or divided (SPLIT) rings and cuffs.

MATERIALS

All CarcoTex / SG gaskets come standard with the following fabric-reinforced materials (the sealing ring does not include fabric):

NBR (S800)

H-NBR (HT700)

FPM (Z400)

PTFE powder is evenly dispersed in the compound, which reduces friction and increases wear resistance, i.e. durability. To further reduce friction (especially for water hydraulics) and to increase the sliding speed (up to 3 m/s), seals with additional Carcoflon spraying on dynamically loaded surfaces (outer or inner diameter) can be supplied on request. For ordering seals with Carcoflon, the material code will change to S820, HT720 or Z420.

Operating conditions:

Pressure up to 350 bar

Max. speed up to 1.0 m/s

Temperature resistance:

NBR - fabric -40 °C / +120 °C

H-NBR - fabric -40 °C / +170 °C

FPM - fabric -20 °C / +200 °C

For more detailed design information and information on available seal sizes, please refer to the datasheet or our colleagues will be happy to provide you with this information.