CarcoTex SP

CARCOTEX SP is a robust, straight-through hydraulic seal suitable for the most severe conditions in both oil and water hydraulic systems. The symmetrical profile allows the SP type to be used as a piston or plunger seal at working pressures up to 630 bar. This is particularly true for the high loads that arise on presses when extruding steel, aluminium, copper and brass horizontally, or for high impact loads (e.g. vertical forging presses).

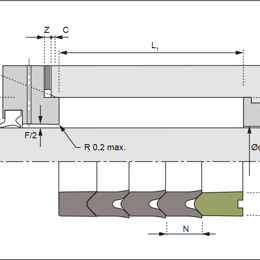

The sets always consist of:

one flexible pressure ring, which is made of a characteristic green elastomer with optimal mechanical properties; the circular protrusions, acting as elastic elements, optimise the required axial preload of the sealing set

one or more V-cuffs of extremely robust profile made of rubber reinforced with fabric; the cuffs have excellent wear resistance even at pressures up to 630 bar

one heavily dimensioned retaining ring made of rubber reinforced with a special fibre - Kevlar®; this new combination ensures very high mechanical strength and anti-extrusion resistance

Carcotex / SP kits are generally supplied with split (SPLIT) rings and cuffs. For large presses and plunger diameters, where this type is often used, this facilitates assembly or disassembly.

MATERIALS:

All Carcotex seals come standard with the following fabric reinforced materials:

NBR (S800)

H-NBR (HT700)

FPM (Z400)

PTFE powder is evenly dispersed in the mixture, which reduces friction and increases wear resistance, i.e. durability. To further reduce friction (especially for water hydraulics) and to increase sliding speed (up to 3 m/s), seals with additional Carcoflon spraying on dynamically loaded surfaces (outer or inner diameter) can be supplied on request. For ordering seals with Carcoflon, the material code changes to S820, HT720 or Z420.

Operating conditions:

Pressure up to 630 bar

max. speed up to 1.0 m/s

Temperature resistance

NBR - fabric -40 °C / +120 °C

H-NBR - fabric -40 °C / +170 °C

FPM - fabric -20 °C / +200 °C

For more detailed design information and information on available seal sizes, please refer to the data sheet or contact our staff.