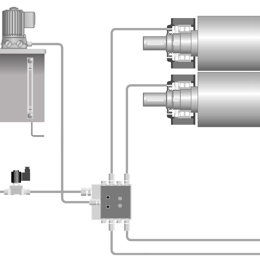

System with progressive dosing of oil

Characteristics:

These systems are designed for lubrication of bearings by the oil-air mixture. The air serves as a transport medium for oil drops and also as a cooling medium to dissipate the technological heat from the bearing space, eventually to create a slight overpressure in the bearing space to prevent the bearings from the dust penetration.

Description:

The oil part of the system is created by the pump (a), which is connected to the mixing unit (b) by delivery pipe directly or through primary progressive divider SSV. The pump is connected to the external oil tank.

The air part is created by air unit (c) with closing valve, from which the air flows to the mixing unit. Units DLOV have 4, 6, 8 or 10 sections, for connection of 4 - 10 lubricated places. Mixing unit consists of the progressive divider and mixing block. The unit oil supply for one output and one piston stroke is 0,2 cm3 . The mixing unit is at the air input equipped by throttle-valve, which enables the air flow for whole mixing unit. The progressive divider of the mixing unit can be equipped by a contactless switch for function controlling. A part of the connection to the lubricated places are hoses and quick-couplings.

Function:

Supplied oil to the mixing unit is gradually divided in unit volume of 0,2 cm3 into particular section of the mixing block. For example if the mixing unit DLOV obtains 0,1 l per minute, it means 500 doses in volume of 0,2 cm3 per minute, that means one dose in 1,2 s into each section of mixing block. The pressure oil forced by piston to the divider flows to the mixing chamber of an appropriate section of the mixing block, in which also flows the pressed air, which flows through the reduction valve with filter and through closing electromagnetic valve to the mixing unit. The valve is during the lubrication time constantly open. The volume of air to the bearing is controlled by throttle-valves for each mixing chamber individually. The total air pressure is set in the throttle valve at the input of the air unit. The air pressure is set on the reduction valve of the air unit, so the flow is not liable to the pressure swings in the network. Although the oil supply to the mixing chamber is gradual, the oil-air mixture at the bearing input is fully continuous and homogenous. The lubrication system can run in the regime of continuous pump working or in the regime of periodical changing of working and standstills periods. _x000D_

Standard elements for lubrication system oil-air with gradual oil supply:

a - Pumps

- Electric gear-pump

- Pneumatic single-stroke for oil - Centro-Matic P-O with stroke volume [cm3] and pressure gearing 7,4-20:1; 39,3-20:1

b - Mixing units

DLOV, DLOV N

Mixing unit DLOV-N:

O- Oil input

V- Air input

V/O- output of air/oil mixture

c – Air units

- Air unit 2/2-1/4"(for mixing units)

Additional parts of the system:

- Accessories (manometer, pressure switch)

- Lubricant distributions (tubes, hoses, screw-coupling, anchoring and assembly material, quick coupling)

Main fields of usage:

Lubrication of rolling storage of working and support cylinders of rolling mills, grinding spindles and other devices placed on rolling bearings with high speeds, with the necessity to dissipate the heat and to displace the dust.